We provide one stop solution to all your power needs

1. Digital Power Management

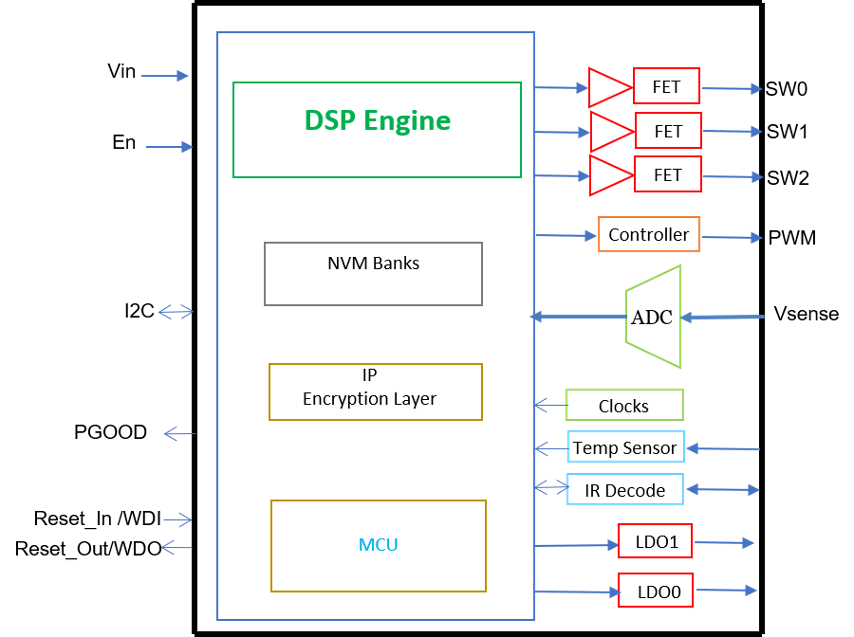

Kompas’ digital power management technology is focused on solving power needs of advanced processors and new information technologies with digital power control & system management implemented as multi-channel programmable digital PMIC for broad applications across product lines and variable loads. The heart of this technology is a hardware platform that integrates digital management and control with power devices along with precision analog circuits. Power loops control is based on a DSP engine that is portable across process technology nodes allowing integration with power train and advanced management functions. Our proprietary “efficient” adaptive signal processing algorithm helps achieve class-leading dynamic response and regulation performance. Our solutions has highly sustainable competitive advantages in term of cost, performance and flexibility. Simply stated, our solution achieves true differentiation: deliver Digital Power Management IC at or below Analog Power cost.

2. High Density Power Module Design

Kompas’ power conversion experts have long history of designing high density power converters for both isolated and non-isolated applications. Our isolated converters range from a few watts up to one kilowatt. On non-isolated side, our analog and digital modules achieve leading power and current densities, and widely serve top customers in a wide range of industries.

3. High Wattage Resonant Power

True to company’s missions of green power, Kompas has developed a resonant power platform that can serve a wide range of new energy and technology sectors. It is based on a proprietary LLC resonant control methodology, and achieves soft switching during turn-on and turn-off over the full range of line voltages, and accomplishes PFC, resonant conversion, isolation with a single-stage topology. Its loop control utilizes an unconventional dual-loop current-mode LLC control that activates switching via pulse-by-pulse current-detect, and thus achieve class-leading response speed, efficiency and reliability. This technology is able to reliably produce pulsed outputs that are demanded in many applications such as battery charging, electrolysis, welding, waste-water treatment and plasma generation. Compared to conventional approaches, our technology can eliminate the PFC stage and life-limiting electrolytic capacitors, thus achieves higher efficiency, smaller size and lower cost.

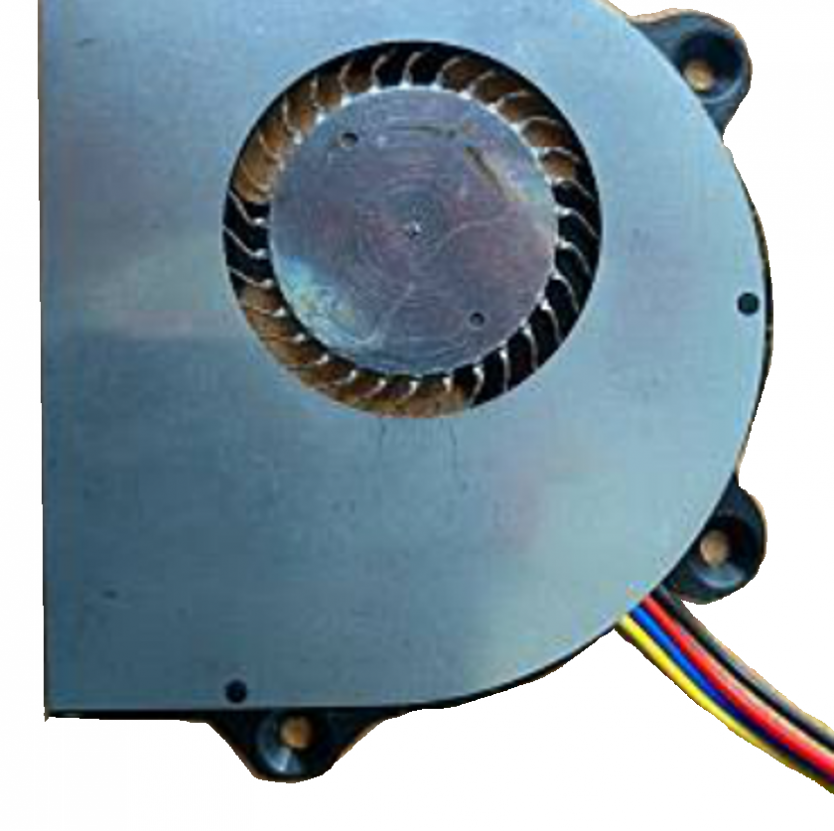

4. Cutting-edge Thermal Design

Kompas’ thermal management team has achieved breakthroughs in advanced thermal design. With the goal of producing the highest performance fan at the lowest profile, the thermal team devoted countless hours of hard work and innovation, achieving many milestones around two aspects: class-leading design and advanced manufacturing. On design side, our team developed proprietary super miniature fan technology along with super low-profile blades that are precise, balanced, effective and low-noise. Mass production of such precision products are made possible only by in-house developed production process that integrates automated assembly with real-time automated inspection technology. Our leading fan products have been successfully utilized and warmly praised by multiple top-tier global enterprises.